027-87511983

027-87511983

(Price negotiable,Please contact the product specialist)

SPECIFICATION

VIDEO

GUIDE

CASE

ADVANTAGE

SOLUTION

Lansun CNC Plasma H/I/U beam cutting machine

Cutting range:width 300-800mm,length 6m,12m,15m or customized

Automical feeding device

Panasonic serve motor

1.Main function: cut section H-beam , I-beam, channel steel, angle steel and other profiles steel;

2.Section steel cutting graphics input method:

Section steel composed of several surfaces. the patterns that need to be cut are often distributed on several surfaces, so the graphics to be cut are 3D graphic structures. The input of 3D cutting graphics is much more difficult than the input of plane cutting graphics.

3.Bevel function of section steel:

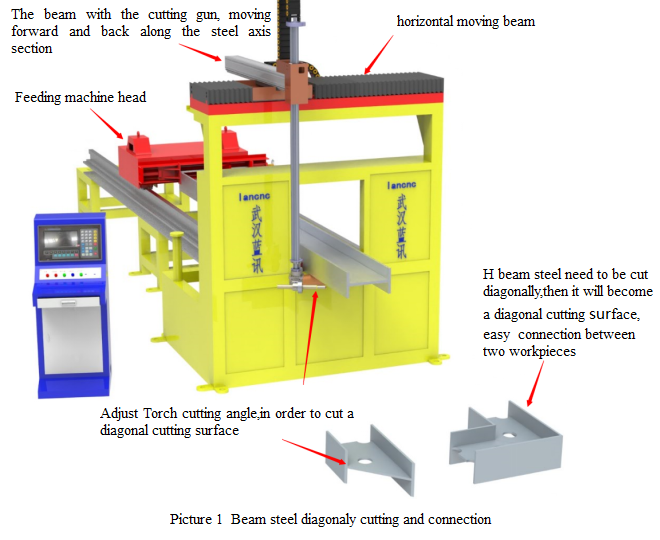

Our machine can achieve beam steel diagonal cutting by excellent CNC control system(Starfire) ,to get 2 connected surface of workpieces .In order to achieve an angled overlap of the two pieces of H-beam, the wings must be cut to bevels. Equipment will adjust the posture of cutting gun (as shown in picture 1)which is at a certain angle with the axis of the H-beam.

By the way,the same cutting machine from most other manufacturers, their cutting guns cannot achieve this posture, namely they don’t have the beveling function of the diagonal cutting wing surface.

4.Telescopic control of the cutting gun along the profile axis.

Cutting various patterns (such as cutting a round hole)on beam steel, is the basic function that profile cutting equipment.there are two available methods: one is that the cutting gun can move along the axial direction of steel (refer to picture 1), and it is completed with the lateral movement of the cutting gun. Another one is that the cutting gun does not use a shaft that moves in the axial direction of steel, it can only be achieved by the feeder head pulling the profile forward and back, and then cooperating with the lateral movement of the cutting gun.

Using the reciprocating movement of the profile to realize the graphic cutting on the profile has technical weaknesses. Since the steel with different length and weight, it will affect the cutting efficiency. When the size of the steel is very large and heavy, it will be greatly affected.so the method is completely unavailable;

5.Steel Scrap

Different structures of section steel cutting machines have large differences in the length of section steel scrap, which will bring different material waste to customers. Therefore, the length of scrap is also a very important indicator to measure the performance of section steel cutting equipment;

6.Material feeding method

At present, there are two kinds of material pushing methods in the world: one is pushing the steel at the end, and the other is that the pushing mechanism is placed near the cutting head, and the push method is reciprocating and backward. The latter equipment has low manufacturing cost, but low efficiency and poor reliability when used.

Lansun steel cutting machine features

1. It can cut H-beam, I-beam, channel steel, and angle steel;

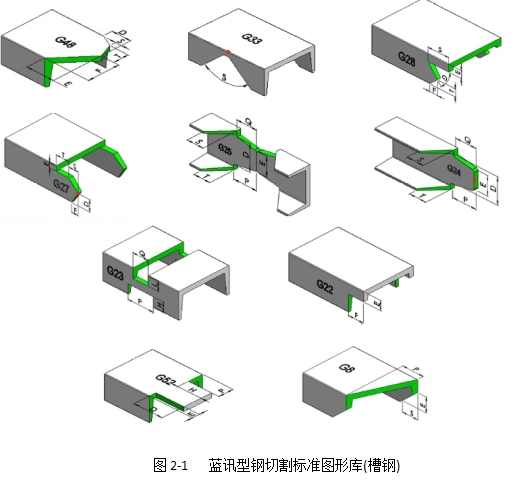

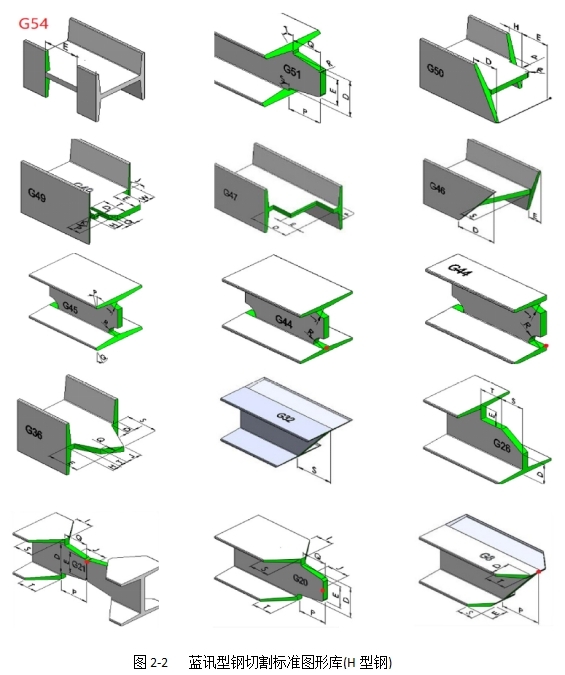

2. Graphical input method, using simple profiles to unfold on all sides, and using plane drawing to complete three-dimensional drawing, the operation is simple and clear; at the same time, the frequently used graphics are made into a parametric graphics library, which greatly simplifies the graphics input method . The company can also add corresponding dedicated graphics libraries according to user needs.

3. Beam steel wings diagonal cutting

The section steel cutting machine is designed with a pendulum shaft (refer to picture 1) to realize the beveling of the section steel wing plate, which can meet the needs of beveling at various angles of the wing plate.

4. Telescopic movement of cutting gun along the beam steel axis section

Our machine is designed with a shaft that telescopically moves the cutting gun along the beam steel axis (refer to picture 1). When cutting the pattern on beam steel, it is done by the axial and horizontal movement of the cutting gun, and beam steel doesn’t need to be moved together. so, fast pattern cutting can be finished very well, and the cutting efficiency,reliability,accuracy can be greatly improved. The feeder head only plays the role of pushing the beam steel forward. No matter how large the beam steel is, it can be precisely pushed into place for precise cutting.

5. Short steel scrap

This machine from Lansun, can help our clients to realize cutting with very short steel scrap or even no steel scrap.

6. Beam steel end pushing method

Our equipment adopts the method of pushing at the end of the beam steel, which can not only ensure the pushing accuracy, but also have better cutting and pushing efficiency.

7.Other features

1) All axes are driven by Panasonic servos, which have better accuracy, reliability and maintainability;

2) Adopt 24kg pushing rail (other suppliers used T rail);

3) The push rail and the head beam are all driven by helical gears, which have better running stability;

4) Japan Panasonic servo dual drive,movement is stronger and more stable;

5) The clamping mechanism adopts hydraulic clamping (mostly pneumatic), which has better clamping reliability;

6) According to user requirements, it can be equipped to flame(oxygen),plasma cutting, or flame(oxygen) & plasma cutting.

H Beam steel profile plasma cutting machine selections

cutting range: width 1-900mm,length 6m,12m,15m.

Machine recommendation according to your cutting requirements

Profile of Lansun section steel cutting machine

Main technical problems of section steel cutting machine

1.Main function: cut section H-beam , I-beam, channel steel, angle steel and other profiles steel;

2.Section steel cutting graphics input method:

Section steel composed of several surfaces. the patterns that need to be cut are often distributed on several surfaces, so the graphics to be cut are 3D graphic structures. The input of 3D cutting graphics is much more difficult than the input of plane cutting graphics.

3.Bevel function of section steel:

Our machine can achieve beam steel diagonal cutting by excellent CNC control system(Starfire) ,to get 2 connected surface of workpieces .In order to achieve an angled overlap of the two pieces of H-beam, the wings must be cut to bevels. Equipment will adjust the posture of cutting gun (as shown in picture 1)which is at a certain angle with the axis of the H-beam.

By the way,the same cutting machine from most other manufacturers, their cutting guns cannot achieve this posture, namely they don’t have the beveling function of the diagonal cutting wing surface.

4.Telescopic control of the cutting gun along the profile axis.

Cutting various patterns (such as cutting a round hole)on beam steel, is the basic function that profile cutting equipment.there are two available methods: one is that the cutting gun can move along the axial direction of steel (refer to picture 1), and it is completed with the lateral movement of the cutting gun. Another one is that the cutting gun does not use a shaft that moves in the axial direction of steel, it can only be achieved by the feeder head pulling the profile forward and back, and then cooperating with the lateral movement of the cutting gun.

Using the reciprocating movement of the profile to realize the graphic cutting on the profile has technical weaknesses. Since the steel with different length and weight, it will affect the cutting efficiency. When the size of the steel is very large and heavy, it will be greatly affected.so the method is completely unavailable;

5.Steel Scrap

Different structures of section steel cutting machines have large differences in the length of section steel scrap, which will bring different material waste to customers. Therefore, the length of scrap is also a very important indicator to measure the performance of section steel cutting equipment;

6.Material feeding method

At present, there are two kinds of material pushing methods in the world: one is pushing the steel at the end, and the other is that the pushing mechanism is placed near the cutting head, and the push method is reciprocating and backward. The latter equipment has low manufacturing cost, but low efficiency and poor reliability when used.

Lansun steel cutting machine features

1. It can cut H-beam, I-beam, channel steel, and angle steel;

2. Graphical input method, using simple profiles to unfold on all sides, and using plane drawing to complete three-dimensional drawing, the operation is simple and clear; at the same time, the frequently used graphics are made into a parametric graphics library, which greatly simplifies the graphics input method . The company can also add corresponding dedicated graphics libraries according to user needs.

3. Beam steel wings diagonal cutting

The section steel cutting machine is designed with a pendulum shaft (refer to picture 1) to realize the beveling of the section steel wing plate, which can meet the needs of beveling at various angles of the wing plate.

4. Telescopic movement of cutting gun along the beam steel axis section

Our machine is designed with a shaft that telescopically moves the cutting gun along the beam steel axis (refer to picture 1). When cutting the pattern on beam steel, it is done by the axial and horizontal movement of the cutting gun, and beam steel doesn’t need to be moved together. so, fast pattern cutting can be finished very well, and the cutting efficiency,reliability,accuracy can be greatly improved. The feeder head only plays the role of pushing the beam steel forward. No matter how large the beam steel is, it can be precisely pushed into place for precise cutting.

5. Short steel scrap

This machine from Lansun, can help our clients to realize cutting with very short steel scrap or even no steel scrap.

6. Beam steel end pushing method

Our equipment adopts the method of pushing at the end of the beam steel, which can not only ensure the pushing accuracy, but also have better cutting and pushing efficiency.

7.Other features

1) All axes are driven by Panasonic servos, which have better accuracy, reliability and maintainability;

2) Adopt 24kg pushing rail (other suppliers used T rail);

3) The push rail and the head beam are all driven by helical gears, which have better running stability;

4) Japan Panasonic servo dual drive,movement is stronger and more stable;

5) The clamping mechanism adopts hydraulic clamping (mostly pneumatic), which has better clamping reliability;

6) According to user requirements, it can be equipped to flame(oxygen),plasma cutting, or flame(oxygen) & plasma cutting.